"CounterTorqueSteer" (countertorquesteer)

"CounterTorqueSteer" (countertorquesteer)

03/06/2015 at 01:46 • Filed to: WIRES

4

4

19

19

"CounterTorqueSteer" (countertorquesteer)

"CounterTorqueSteer" (countertorquesteer)

03/06/2015 at 01:46 • Filed to: WIRES |  4 4

|  19 19 |

Also wired the surround sound. Now just waiting for the TV to pull it all together.

Anon

> CounterTorqueSteer

Anon

> CounterTorqueSteer

03/06/2015 at 02:04 |

|

Megaman X, I approve.

ToyDeathbot

> CounterTorqueSteer

ToyDeathbot

> CounterTorqueSteer

03/06/2015 at 02:05 |

|

Oh my, is that a SNES?

CounterTorqueSteer

> ToyDeathbot

CounterTorqueSteer

> ToyDeathbot

03/06/2015 at 02:06 |

|

indeed it is!

Jordaneer, The Mountaineer Man

> CounterTorqueSteer

Jordaneer, The Mountaineer Man

> CounterTorqueSteer

03/06/2015 at 02:06 |

|

I can haz respost this on thesoundboard http://soundboard.kinja.com/

CounterTorqueSteer

> Jordaneer, The Mountaineer Man

CounterTorqueSteer

> Jordaneer, The Mountaineer Man

03/06/2015 at 02:06 |

|

Absolutely!

ToyDeathbot

> CounterTorqueSteer

ToyDeathbot

> CounterTorqueSteer

03/06/2015 at 02:07 |

|

awesome stuff!

E. Julius

> CounterTorqueSteer

E. Julius

> CounterTorqueSteer

03/06/2015 at 02:41 |

|

Nice! My sister has that exact same TV stand weirdly enough.

DrJohannVegas

> CounterTorqueSteer

DrJohannVegas

> CounterTorqueSteer

03/06/2015 at 03:15 |

|

Nice Technics! I've been thinking about getting a deck which has dbx on it (all my machines are Dolby only), just to try it out. Setup is looking good.

zeontestpilot

> CounterTorqueSteer

zeontestpilot

> CounterTorqueSteer

03/06/2015 at 06:22 |

|

Nice! I used to have a similar set up (5 consoles, one tv), but I never used all the consoles at once, so I put them in storage to keep dust out.

How are you connecting it all? Are you using a box to switch component cables? I have one, they are very useful.

JGrabowMSt

> CounterTorqueSteer

JGrabowMSt

> CounterTorqueSteer

03/06/2015 at 06:31 |

|

My new job is to spend my day making wires look pretty, Im curious how this looks in the back.

edu-petrolhead

> CounterTorqueSteer

edu-petrolhead

> CounterTorqueSteer

03/06/2015 at 09:20 |

|

MEGAMAN X, YESSS!!!!!!!!

CounterTorqueSteer

> DrJohannVegas

CounterTorqueSteer

> DrJohannVegas

03/06/2015 at 09:40 |

|

Thanks. It was my dad's. I'm extremely impressed by the quality that it's putting out.

uofime

> JGrabowMSt

uofime

> JGrabowMSt

03/06/2015 at 16:49 |

|

I do not envy you, cable management drives me insane.

JGrabowMSt

> uofime

JGrabowMSt

> uofime

03/06/2015 at 17:26 |

|

Its kind of therapeudic. In a strange way. I have a complex job Im wiring Monday morning, I can post pics when its done.

uofime

> JGrabowMSt

uofime

> JGrabowMSt

03/06/2015 at 17:43 |

|

I'd definitely be interested in seeing your techniques for bringing chaos into order

JGrabowMSt

> uofime

JGrabowMSt

> uofime

03/10/2015 at 22:36 |

|

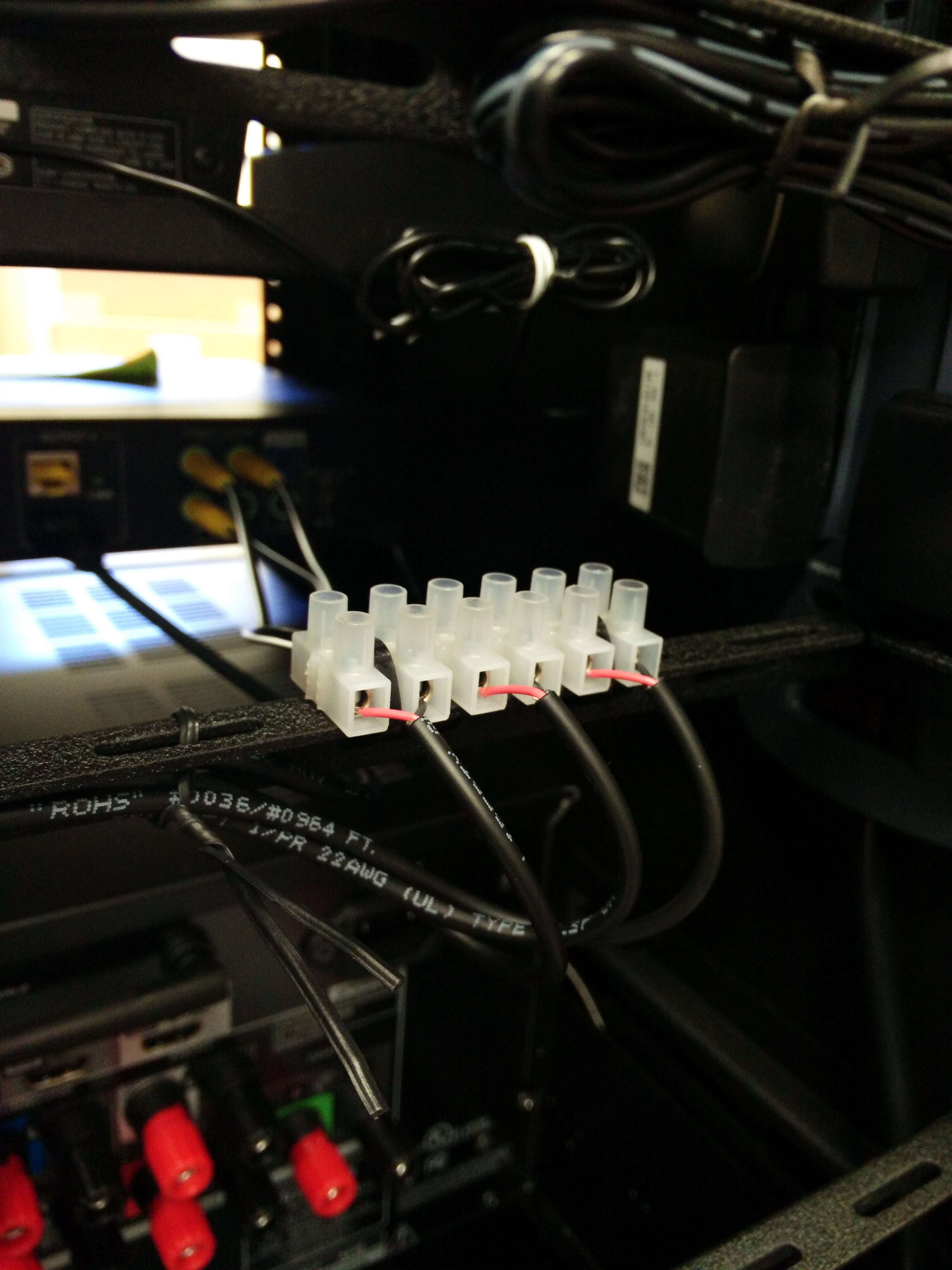

I couldn't disappoint you, so here's a couple examples, though none of these systems are truly wired to their maximum capabilities, as they're simply wired up to be a plug and play system when installed in the field (I don't work in the field for these installations).

Some installs are more "complete" than others, but it's all 100% dependent on the job. Some are designed to be very "future proof" where there's room for expansion, others are not. Depends on where they're being installed, and what the system has to do.

A couple of smaller details that are still changing, mainly because I try things out and either 1) don't like how it looks/works or 2) I find something cheaper and easier to install. Once I run out of terminal blocks, I'm not going to order any more, I have a much more elegant solution I'll be using next.

Typically it takes me about 10-15 hours for basic wiring of a rack, could be more than 20 hours in a more complete rack. Factor in another 3-5 hours in the field sometimes (I don't get every piece of equipment to install).

Eventually I'm looking to stop using zip ties for everything, but the bigger issue is that velcro is 1) far bulkier 2) not as flexible 3) requires more velcro for the same job. Sometimes there are spacial constraints of where a rack will be put, or a customer will specifically request a certain type of rack. Not all of these pictures are quite "perfect," but I'm not ashamed to show them. I do have a Wall of Shame in the doorway to my workshop as well. Clients and coworkers sometimes stare at what I'm doing for a while (or racks that are built and waiting for delivery) and it's always fun to hear how impressed they are.

uofime

> JGrabowMSt

uofime

> JGrabowMSt

03/11/2015 at 09:38 |

|

That is definitely some impressive work. Thanks for sharing.

Zip -ties are great for semi-permanent stuff, why do you want to get away from them? This is clearly some hi end stuff, is it just for the classiness factor of hook and loop straps?

JGrabowMSt

> uofime

JGrabowMSt

> uofime

03/11/2015 at 10:16 |

|

These racks are technically permanent installation pieces. Once they're programmed and we close the door on it after installing on site, they aren't really meant to be changed. That said, equipment failures can happen, or clients can want an upgrade. Part of my job is to essentially find a balance between the permanent installation aspect, as well as making sure if we need to replace equipment (and are unable to get an identical replacement) that wiring up a new unit wouldn't involve cutting the entire thing apart, and having to re-do the work again. Moving to velcro means it's just a few seconds away from freeing a cable, but it doesn't hold the cables nearly as securely in place. Some of the cables are very good at retaining shape and I only really need to zip tie them together in order to make it look neat, but if a cable goes bad (not likely, but within the realm of possibility) it shouldn't take 2-3 hours to cut out, replace and bundle everything back up.

I've thought about conduits with cable holders, cable ladders, the whole bit, but it's hard to find a solution that will work on all the racks. The 20" deep racks are a PITA because with a shelf in, you can't even fit a power strip, much less a normal lacing bar, but so far, zip ties aren't going anywhere because it has the cleanest look when it's done. I'm all for keeping zip ties, but with some of the work I've done, it'll take me plenty of time to cut things out and change it. We're getting better (I've been here since January) and definitely making improvements, but it will be a long slow process before things are truly figured out. I have a couple of ideas, but have yet to figure out how to implement them without being too much of a time vampire. For the time being, I'm both making wires and placing custom orders for specific lengths which is a vast improvement (most power cables with equipment is 6' long, where I may need 18-36" in most racks). Power cables are the worst offenders, right up there with RS232 and the two prong power cables. RCA, RJ45, RG6, coax, and IR cables I can custom make very easily and quickly. I'm looking to eventually start doing custom RS232 because I finally have a bag of connectors, but it takes a long time and some equipment has non-standard pinouts, or a male vs female jack on the unit itself.

But yes, very high end installs. Compared to my own home theater (or home theaters that I personally install), these setups are much more complicated. Much like the OPs system actually, and cable management is a walk in the park in comparison (hide extra wire behind the cabinet vs make sure wires are neat and accessible from the rear). But here with these rack builds some of the equipment is super cheap, other equipment is insanely expensive. The things I could buy with the money that it costs for these final installs......

uofime

> JGrabowMSt

uofime

> JGrabowMSt

03/11/2015 at 11:08 |

|

The custom length cables definitely help keep it looking clean.

You definitely have a hard job